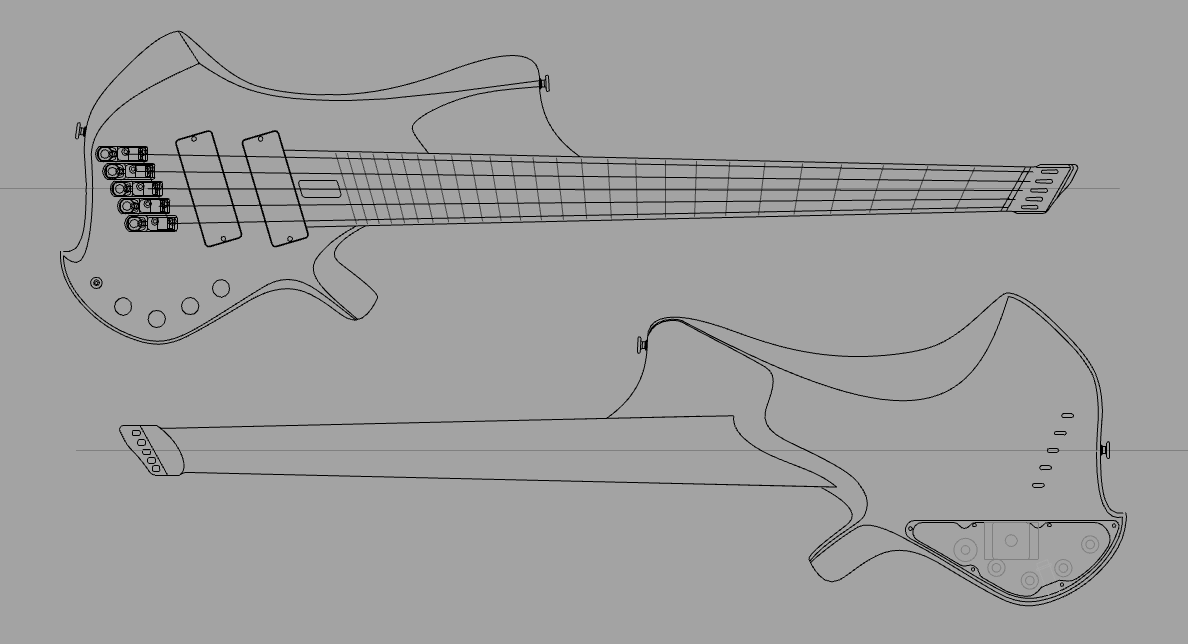

HEADLESS ENNEA BASS

I wanted to make a headless Ennea bass for a long time, but at first I couldn’t solve this design problem. Headless bridges require a cutout for knob access and it just doesn’t play nicely with the Ennea shape. That was until the Riviera Bridge came out, which has a top-facing tuning knob. I was super happy about it and announced that the headless Ennea is now available for order.

But there’s one problem. Actually, two problems. It’s not a locking bridge, meaning it’s designed to work with a string ball, and the loose end of the string should be locked at the headstock. Why is it a problem? First, most bass strings taper at 1.5” from the ball and the layout of this bridge is such that the taper pretty much hits the saddle, making it impossible to intonate. Second, with my 36” scale on a B string, the other taper exactly hits the nut, which is totally unacceptable. Plus, I just hate string ends poking out of the headstock.

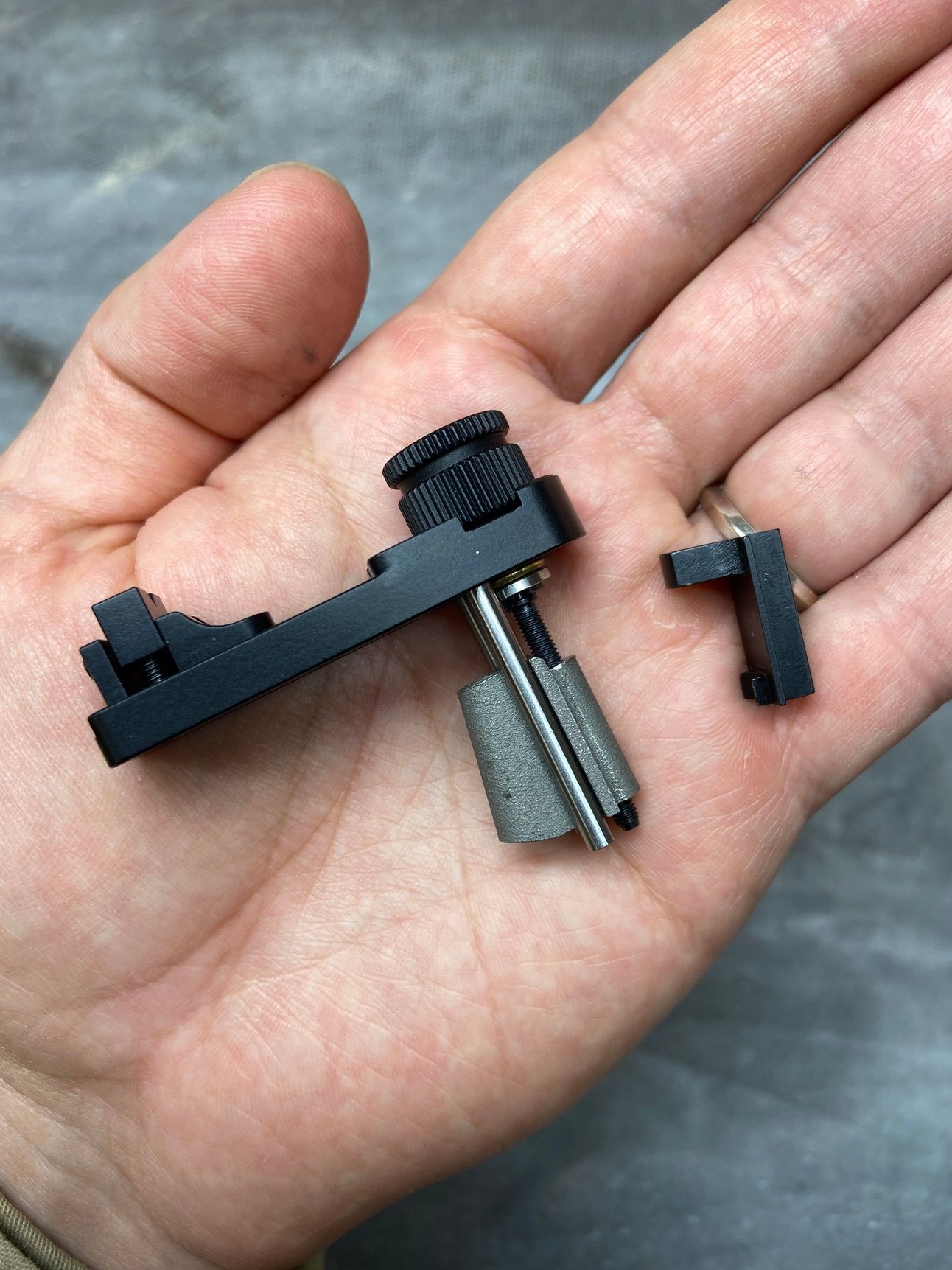

So I resigned to find strings that fit those lengths and design a sleek headstock string-locker. I went as far as buying all components for the locker and started cutting a test neck, but I still wasn’t quite happy with the idea. And then it hit me… The tuning part of the bridge is replaceable and I can design my own locking part!

The idea was great, but I so didn’t want to machine it - it would have been a nightmare to set up. Thankfully I remembered that this is the part where metal 3D-printing is the way to go. I still had to tap the threads myself and the most difficult part was finding a left-handed M3 tap in North America 😂